Page 20 - Product Catalogue December 2023

P. 20

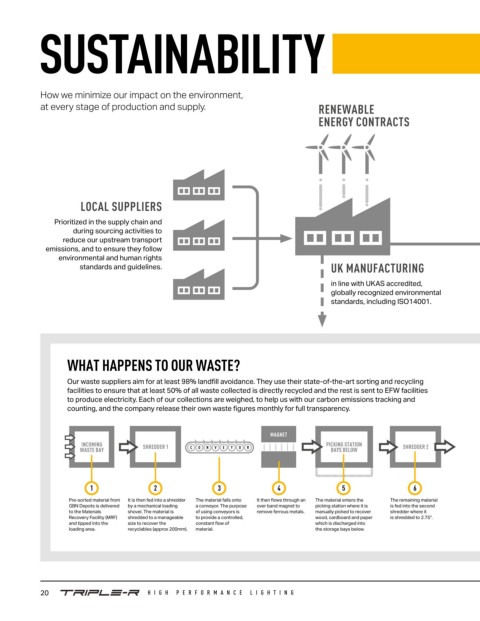

SUSTAINABILITY

How we minimize our impact on the environment,

at every stage of production and supply. RENEWABLE

ENERGY CONTRACTS

LOCAL SUPPLIERS

Prioritized in the supply chain and

during sourcing activities to

reduce our upstream transport

emissions, and to ensure they follow

environmental and human rights

standards and guidelines. UK MANUFACTURING

in line with UKAS accredited,

globally recognized environmental

standards, including ISO14001.

WHAT HAPPENS TO OUR WASTE?

Our waste suppliers aim for at least 98% landfill avoidance. They use their state-of-the-art sorting and recycling

facilities to ensure that at least 50% of all waste collected is directly recycled and the rest is sent to EFW facilities

to produce electricity. Each of our collections are weighed, to help us with our carbon emissions tracking and

counting, and the company release their own waste figures monthly for full transparency.

MAGNET

INCOMING SHREDDER 1 PICKING STATION SHREDDER 2

WASTE BAY C O N V E Y O R BAYS BELOW

1 2 3 4 5 6

Pre-sorted material from It is then fed into a shredder The material falls onto It then flows through an The material enters the The remaining material

GBN Depots is delivered by a mechanical loading a conveyor. The purpose over band magnet to picking station where it is is fed into the second

to the Materials shovel. The material is of using conveyors is remove ferrous metals. manually picked to recover shredder where it

Recovery Facility (MRF) shredded to a manageable to provide a controlled, wood, cardboard and paper is shredded to 2.75".

and tipped into the size to recover the constant flow of which is discharged into

loading area. recyclables (approx 200mm). material. the storage bays below.

20